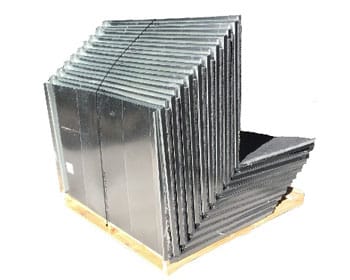

Insulated Rectangular Ducts

Spiral Pipe of Texas manufactures a wide range of internally insulated rectangular duct products. Insulation is necessary for most HVAC duct applications, ducts internally insulated by the manufacturer offer consistent quality, greater material options, better appearance, liner protection, and reduced field labor. There are several methods and options for insulating rectangular ducts, we strive to produce products that not only meet the highest requirements of performance and function, but also utilize materials and methods that are environmentally conscious.

Our standard of fabrication for typical HVAC duct is in accordance with the SMACNA HVAC Duct Construction Standard – Metal and Flexible (2005). We can also fabricate in accordance with the SMACNA Rectangular Industrial Duct Construction Standards (2004) or custom standards. Factory insulated rectangular ducts are provided as either Internally-Lined Rectangular Ducts or Double-Wall Rectangular Ducts.

Internally-Lined Rectangular Ducts

Internally-lined rectangular ducts are fabricated with an outer metal shell and an insulation media glued and mechanically fastened to the interior surface. The outer metal shell is the structural basis of our design. We provide all materials, gauges, seams, and joints available to SPOT’s single-wall products. Duct liner fasteners (weld pins) are the primary mechanical attachment of the liner to the metal outer shell and they are spaced in accordance with Figure 7-11 of the SMACNA HVAC Duct Construction Standards – Metal and Flexible (2005).

Additional attachments are provided from a resin adhesive applied with minimum 90% area coverage between the metal outer shell and liner media. Our standard adhesive is APB 5050 from Warren Adhesives, Inc. (HMIS ratings: Health – 0, Flammability – 0, Reactivity – 0). The liner media is installed with the velocity-rated side facing the airflow. Intended velocity should be stated when ordering internally lined rectangular ducts. Velocity determines the maximum spacing of mechanical fasteners, at velocities exceeding 4000 FPM, necessitates the use of metal nosing on the leading edge of each duct section.

The outer metal shell is the structural basis of our design.

The following liner media are available for internally-lined rectangular duct from Spiral Pipe of Texas:

Flexible Fiber Glass Duct Liner – standard product Johns Manville Linacoustic® RC made from glass fibers bonded with a thermosetting resin. The velocity-rated airstream surface is protected by a combination of a flexible glass mat and an acrylic coating to provide a smooth airstream surface.

- Available thicknesses: ½”, 1”, 1 ½” and 2”

- Maximum operating temperature: 250°F (ASTM C411)

- Maximum air velocity: 6,000 FPM (ASTM C1071)

- Fungi resistance: Does not breed or promote (ASTM C1338), no growth (ASTM G21)

- Bacteria resistance: No growth (ASTM G22)

- Surface burning characteristics: Flame Spread – 25, Smoke Developed – 50 (ASTM E84, UL 723, NFPA 255, NFPA 90A and 90B, NFPA 259)

- Thermal performance (ASTM C518): ½” R = 2.2, 1” R = 4.2, 1 ½” R = 6.3, 2” R = 8.0

Elastomeric Foam Duct Liner – standard product Armacel AP/Armaflex®

- Available thicknesses: 1”, 1 ½” and 2”

- Maximum operating temperature: 220°F (ASTM C534)

- Maximum air velocity: 10,000 FPM (ASTM C1071)

- Mold Growth: Passed (UL181)

- Fungi resistance: Passed (ASTM C1338 and ASTM G21)

- Bacteria resistance: Passed (ASTM G22)

- Surface burning characteristics: Flame Spread – 25, Smoke Developed – 50 (ASTM E84) — for 1” Armaflex® only. Does not pass for 1 ½” and 2”. AP Armaflex FS® must be specified for thicknesses greater than 1” if 25/50 standard must be met.

- Thermal performance (ASTM C 177 or ASTM C518): 1” R = 4.2, 1 ½” R = 6, 2” R = 8

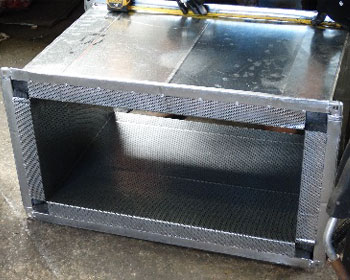

Double-Wall Rectangular Ducts

Double-wall rectangular ducts utilize the same outer metal shell and insulation media as our Internally-lined rectangular ducts, but have an additional metal inner shell between the insulation and the airstream. This provides some additional characteristic to the duct, as well as allowing a few more insulation options. Construction is in accordance with Chapter 8 “Double-Wall Duct Construction” of the SMACNA HVAC Duct Construction Standards – Metal and Flexible (2005). The outer metal shell is still the structural basis of design. The inner metal shell can be either solid metal or perforated metal (standard 3/32” holes on 3/16” centers – staggered – 23% open area). Double-wall construction also gives you the option of a Mylar erosion barrier between the insulation media and the inner metal shell. Available insulation media are:

Insulated rectangular ducts use the same metal shell and insulation, but have an additional metal inner shell.

Double-wall rectangular duct uses the same insulation media as Internally-lined rectangular duct, as mentioned previously. Please see both flexible fiber glass duct liner and elastomeric foam duct liner details listed above under Internally-lined rectangular duct. In addition to these there is one more insulation media detail below:

Net 1.0 PCF density glass mineral wool – standard product is 0.75 PCF density Knauf Atmosphere™ DuctWrap with ECOSE® Technology (provided in thickness 50% greater than annular space and compressed to 1.0 net PCF density). Available in 1” and 2” thickness.

Duct Connectors

Insulated rectangular ducts from Spiral Pipe of Texas are available with the following transverse connector options:

- S & Drive – T-1 drive slips with either T-6 hemmed S slips, T-11 standing S, or T-13 standing S (not recommended for double-wall)standing S (internally-lined duct only — not recommended for double-wall)

- T-25b TDF Flanged Transverse Connections

- Slip-On Ward-J flange (used when gauge exceeds 18 ga.)

- Butt-Welded (raw ends)

- Welded Angle Iron Frames

- ½” Weld Flanges

Liner Terminations at Transverse Connections

- The standard fiber glass duct liner used with our Internally Lined Rectangular Ducts (Johns Manville Linacoustic® RC) includes a factory-applied edge coating.

- For all Double-Wall Rectangular Ducts, the metal inner liner is folded outward at ends and transverse connections, isolating the insulation media from the airstream and forming a metal-to-metal butt joint between duct sections.

Browse OurDuct Solutions

Spiral Pipe of Texas (SPOT) fabricates high quality, MADE IN THE USA sheet metal products for the heating, air conditioning and ventilation (HVAC) industries.