Benefits of Spiral Rounds Duct

Learn about the benefits of spiral round duct for your facility.

If you could do just one thing to your duct design that would make it more energy efficient and less expensive, would you do it?

You might recognize the two symbols above. The one on the left is used to denote that a duct will be round. The one on the right denotes that a duct will be flat oval. Most of the time, for a typical HVAC system, they indicate you want spiral duct.

If you could do just one thing to your duct design that would make it more energy efficient and less expensive, would you do it?

SPOT Fabricates Its Own Flanges

This helps us control fabrication time and allows for competitive pricing.

CAD / CAM Software

Before fabrication, pipe specifications are carefully planned using CAD/CAM software.

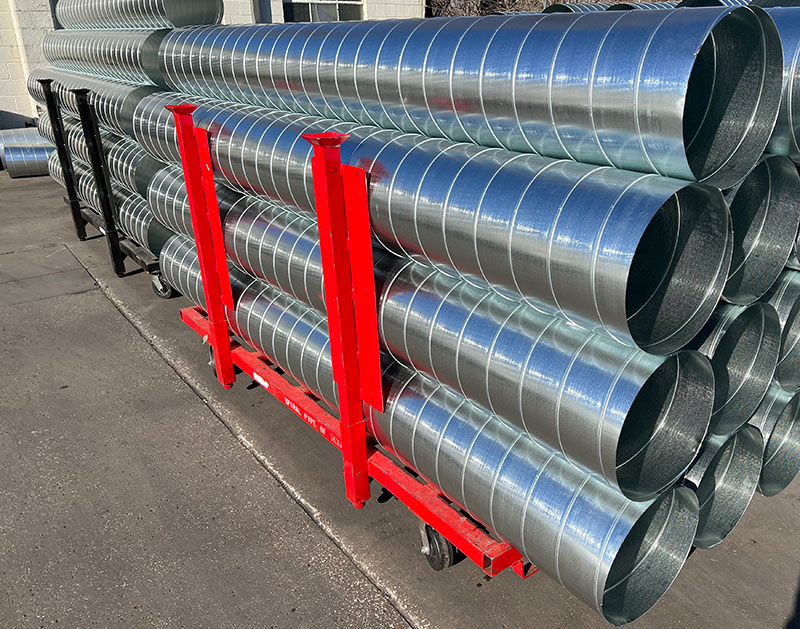

Spiral Pipe Fabrication

Each piece of spiral pipe is cut to length to save installation time in the field.

Plasma Torches Cut CAD/CAM Designed Parts for Each Job

Technology utilized to speed fabrication time and reduce material waste.

Galvannealled Spiral Duct and Fittings

Internally lined with factory mounted taps. Ready to be installed and painted.

Product Type

SMACNA Standard

Single Wall/Double Wall

Resource Type

Spiral Pipe of Texas (SPOT) fabricates high quality, MADE IN THE USA sheet metal products for the heating, air conditioning and ventilation (HVAC) industries.