Pressure & Duct Construction

Guidelines for spiral duct construction and pressure.

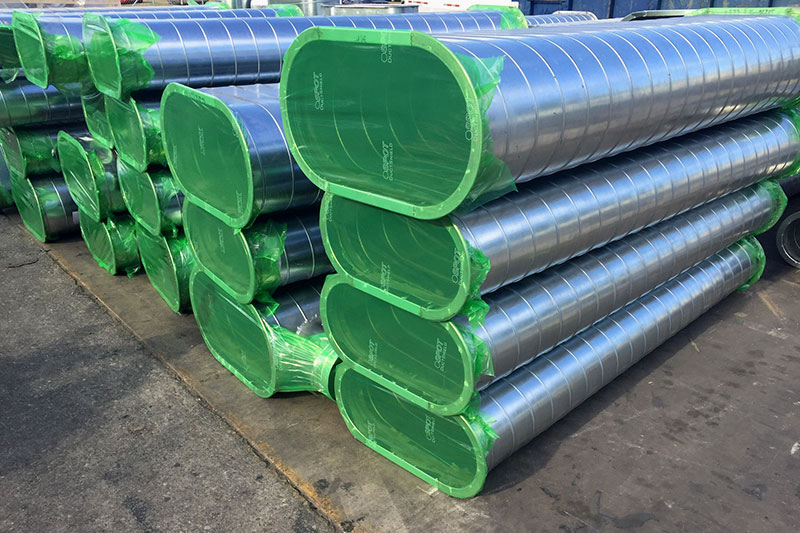

Architects, engineers, and building owners continue to become fans of spiral flat oval duct for their commercial projects. In addition to its attractive appearance, spiral flat oval has all the same benefits as traditional spiral round duct but can also fit into spaces where clearance is a challenge.

Here at SPOT we consider ourselves experts in spiral oval duct fabrication with years of experience as well as unmatched sizing capabilities- minor access from 3” up to 36”.

Many sheet metal contractors who fabricate their own duct choose to partner with SPOT to handle their flat oval requirements.

We stand ready to quote and fabricate any spiral flat oval duct required on your next project.

In comparing a simple duct system — 40’ of straight duct, a 90-degree elbow, a transition and three installed taps — it suggested that the installed rectangular duct section ($775 to $1375) was less expensive than the installed flat oval duct section ($975 to $2100). After 25 years and thousands of real-world cases where that suggestion was proven to just not be true, we are still battling the 80’s mentality that “flat oval is too expensive.”

A lot more than just the “cost” has changed in the last 25 years. If just one of the following statements is true about your upcoming project, you need to immediately change your design to one using round and spiral flat oval duct.

If yours is a commercial HVAC project, you probably answered yes to most, if not all, of the above statements. We are going to give you the reasons why spiral flat oval duct is your best choice to satisfy each of those concerns:

Exposed Corrugated Flat Oval Duct with SPOT Flange Connection

Oval used in adaptive reuse of historical building converted to creative office space.

CAD/CAM Software Utilized

SPOT assembly drawings provided with all spiral round and flat oval shipments.

Product Type

SMACNA Standard

Single Wall/Double Wall

Resource Type

Spiral Pipe of Texas (SPOT) fabricates high quality, MADE IN THE USA sheet metal products for the heating, air conditioning and ventilation (HVAC) industries.