Insulated Round Duct

Most HVAC ducts need to be insulated. At Spiral Pipe of Texas, our home area encompasses regions with high fluctuations in both temperature and humidity. It’s no surprise that we have been at the forefront of developing and implementing insulated duct products. Factory insulated duct products reduce field labor, as well as giving consistency and product features you won’t get with thermal wrap. Duct insulation is also critical in reducing HVAC system noise. Here are some of the product options for round insulated duct that are available from Spiral Pipe of Texas.

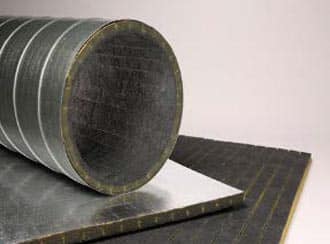

Double-wall Insulated Round Ducts

Double-wall construction allows you to contain the insulation media between an inner and outer metal shell. The insulation is protected from external damage – a critical concern for ductwork on rooftops and out of the building envelope. Where ducts are exposed to view, insulation is concealed for a more pleasing appearance. The internal metal shell gives protection from insulation erosion, maintains a smooth duct cross-section, and makes cleaning the ducts easier. There are quite a few options available for double-wall ducts, so it’s important that critical features are specified. Here are some of them:

Outer Metal Shell

For HVAC air ducts, the outer shell is the structural and pressure containment portion of the product, and is the basis of construction. Unless noted otherwise, double-wall ducts are fabricated in accordance with Chapter 8 of the SMACNA HVAC Duct Construction Standards Metal and Flexible (Third Edition – 2005) and the outer shells are constructed in accordance with Chapter 3 of the same standard. It is important to note that the dynamic airflow performance of a duct system is based on the inner shell, and most duct sizing on mechanical drawings are I.D. Yet, it is the outer shell that determines gauge, reinforcing and construction, as well as defining how a duct fits within the physical constraints of a building. Fitting dimensions (elbow centerline radii, tee fitting length, tap clearance to end, etc.) are based upon the outer shell, not the inner.

Straight duct construction – available as spiral lock-seam duct (corrugated and non-corrugated) and welded longitudinal-seam duct.

Fitting construction – fully-welded or tack-welded and sealed.

Materials – G90 Galvanized Steels, A-40 and A-60 Galvannealed Steel, Black Iron, 3003 Aluminum, 304 and 316 Stainless Steels, PCD (Polyvinyl Coated Galvanized), AgION (Antimicrobial Steel).

Gauges – 26 to 16 for galvanized spiral lock-seam, 28 to 18 for stainless steel spiral lock-seams, 0.025” to 0.080” for aluminum spiral lock-seams, 22 gauge to 3/8” for welded longitudinal-seam duct.

Appearance and finish – standard factory finish (no special cleaning, welds spray-painted, mill markings, labels and piece-marks visible), paint-ready (welds not painted, removeable labels), and factory painted. SPOT has additional literature giving more specific details for our architectural duct products.

Inner Metal Shell

Solid – standard metal liner in gauges and construction to contain the insulation and maintain concentricity and structural integrity. Available in all materials offered above for outer shells.

Perforated metal – standard material is a 23% open area pattern with 3/32” holes on 3/16” centers, staggered.

Perforated metal with erosion barrier – standard perforated material with an additional protective layer of Mylar between the insulation and the perforations opening into the airstream.

Note –– the Mylar film is an excellent erosion and vapor barrier, but it’s use may affect the acoustical performance of a double-wall duct, as well altering the flame spread and smoke development numbers.

Insulation Layer

Standard Material – our standard product is a 0.75# density Knauf Atmosphere™ Duct Wrap with ECOSE® Technology. The insulation is thicker than the intended annular space between metal shells (1.5” thick for 1” nominal spacing) so that net density is after fabrication is approximately 1.00#. This material is a highly resilient inorganic glass mineral wool with bio-based binders. It does not contain phenol, formaldehyde, acrylics, or artificial colors. It carries a GREENGUARD Gold Certification.

Thickness — standard 1” and 2” annular spacing. Other thicknesses available.

Installed R-Value — R=4.2 for 1” spacing, R=8.4 for 2” spacing

Surface Burning Characteristics — Flame Spread 25 and Smoke Developed 50 (tested in accordance with UL 723, ASTM E 84, and NFPA 255.

Temperature Range — up to 350°F

Mold Growth — no growth (ASTM C 1338)

Note — metal spacers are not used to maintain concentricity between inner and outer shells. Though sometimes specified, they make duct assembly with slip-fit transverse joints more difficult, create thermal bridges between the interior and exterior of the duct, and have a negligible effect on actual R-value. In actual practice, insulation compression is more of a concern for larger diameters of duct where double-wall flanges are typically used for transverse connectors, eliminating any need for spacers.

Made with EPA registered Microban® antimicrobial product protection.

Alternative Material – Armacell AP/Coilflex® elastomeric foam duct liner. Fiber-free, non-particulating foam alternative to glass fiber insulations. Standard 1” thickness (larger annular thicknesses obtained by wrapping successive layers) with R-value R=4.2. Flame spread/smoke developed index of 25/50 (ASTM E 84) and temperature use limit up to 180°F. GREENGUARD Gold Certified.

Armacell AP/Coilflex® elastomeric foam duct liner.

Single-wall Insulated Round Ducts

Spiral Pipe of Texas has been a pioneer in the use of Johns Manville Spiracoustic Plus® round duct liner system, providing some of the largest systems ever produced with outer shell diameters up to 92”Φ. Like our double-wall products, the outer metal shell is the basis of construction. The Spiracoustic Plus® liner has factory-made, evenly spaced kerfs that, when inserted into the outer metal shell, allow it to evenly conform to the inside of the duct. The product is a high-density fiber glass board with a factory-applied black acrylic coating applied to the surface and transverse edges, JM’s Permacoat®.

After the liner is assembled into the outer metal shell, SPOT provides the finishing touches by using JM’s SuperSeal® coating product to dress up any exposed edges, as well as utilizing mechanical fasteners as needed to assure the liner stays permanently affixed.

Spiral Pipe of Texas single-wall insulated duct with Spiracoustic Plus® liner may have some advantages for your project over traditional double-wall insulated products. With no metal inner shell, the product is lighter in weight – as much as 30% lighter in many sizes. Labor needed for transverse joint assembly can also be reduced since a single slip joint is all that is necessary. The product is ideally suited for systems with long, straight runs of duct –– gymnasiums, cafeterias, airports, sports arenas, and convention centers.

Thicknesses — 1”, 1 ½” and 2”

R-Value (tested in accordance with ASTM C518) — 1” (R=4.3), 1 ½” (R=6.4), 2” (R=8.4)

Diameters Available (I.D.) — 1” (4” to 90”Φ), 1 ½” (11” to 84”Φ), 2” (14” to 88”Φ)

Density — 4.0 pcf

Operating Temperature — up to 250°F

Maximum Air Velocity (ASTM C1071) — 6000 fpm

Surface Burning Characteristics — Flame Spread 25 and Smoke Developed 50 (tested in accordance with UL 723, ASTM E 84 and NFPA 255)

Fungi Resistance — does not breed or promote (ASTM C1338), no growth (ASTM G21)

Bacteria Resistance — no growth (ASTM G22)

Browse OurDuct Solutions

Spiral Pipe of Texas (SPOT) fabricates high quality, MADE IN THE USA sheet metal products for the heating, air conditioning and ventilation (HVAC) industries.