Benefits of Spiral Round Duct in HVAC Systems

If you could do just one thing to your duct design that would make it more energy efficient and less expensive, would you do it?

1. ASHRAE Advanced Energy Design Guides won’t be achieved

It’s a big deal to try and reduce energy use in commercial buildings by 30% and 50%. ASHRAE has worked extensively to help its’ members achieve these goals by compiling research and assembling cost feedback that might be impractical for a single engineering firm to do. The Advanced Energy Design Guides were written by fellow engineers, not a trade organization or contractor. They specifically state “Round duct is preferred over rectangular duct. However, space (height) restrictions may require flat oval ductwork to achieve the low-turbulence qualities of round ductwork.”

2. More turbulence, and turbulence is bad

You don’t even have to be an engineer to know those square corners of rectangular ductwork cause far more turbulence than no corners (round) or rounded corners (flat oval). We all kind of know without trying it that putting a rectangular drain line downstream of your toilet would pretty much assure regular visits from the plumber. Things just don’t flow as well when you have square corners. With airflow, that gives you two unwanted problems that are directly related to turbulence – higher pressure drops and increased noise.

3. More duct will be needed

The only reasonable way to decrease pressure loss and noise in a duct (other than change its’ shape) is to slow the air down. Yes, you need to make the duct bigger. For aspect ratios 2:1 to 4:1 – pretty typical for rectangular ducts – the perimeter relative to an equivalent round diameter is 30 to 55% (2013 ASHRAE Handbook – Fundamentals, Chapter 21 “Duct Design”, page 12). We’re not making this up! It’s pretty easy for you to confirm after a couple of moments on your Ductulator.

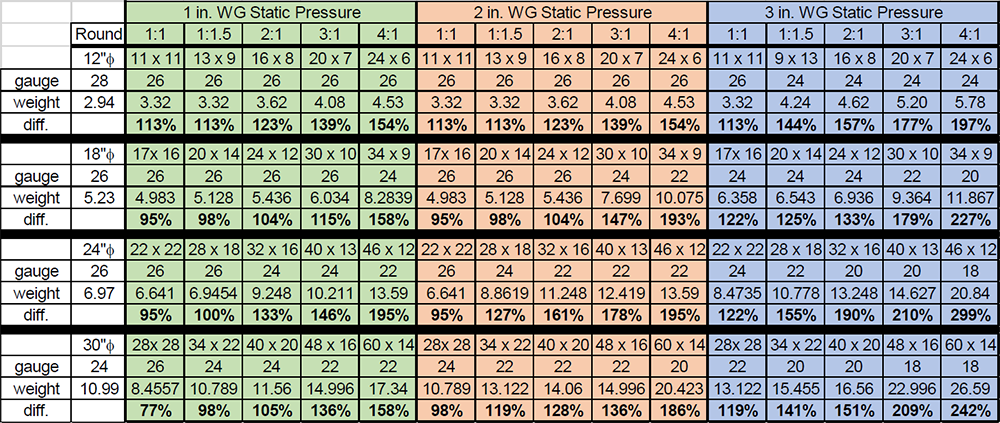

4. Duct will weigh more, therefore more hardware will be need to be screwed or welded

You’ve probably heard or used the term ”built in accordance with SMACNA”. That’s most often referring to the “2005 SMACNA HVAC Duct Construction Standards – Metal and Flexible”. It is an excellent structural standard that’s mostly showing you one thing – how to limit deflection. Whether dealing with how much an assembled length of duct deflects (hanger spacing and seismic bracing) or how much the walls of a duct deflect (limiting metal fatigue, low-frequency noise generation and how the duct may impede other items within the building), the goal is to keep a duct system as static and motionless as possible. Flat surfaces deflect. Round/curved surfaces have little-to-no deflection in positive and low pressures. The SMACNA manual will have you increase the gauges or add reinforcing to limit deflection. Not only do you have to increase the amount of duct (perimeter) to reduce pressure loss and noise, you also have to increase the weight of that perimeter to reduce deflection. Here are a few examples:

5. Duct cost will increase

The cost of ductwork, both to buy/make and install, has a direct correlation to weight. Keep in mind the chart above. Even if someone says their cost per pound is less for rectangular duct, that’s quickly negated because it takes a lot more pounds of rectangular duct to carry the same amount of air. Installation labor skews even more in favor of round duct. Weight-based labor formulas generally allow 50% more pounds per man-hour for installing round and flat oval spiral duct versus rectangular. If you pick an example from the chart above where rectangular duct weighs 50% more than round spiral duct, it only takes 44% of the labor to install the round spiral duct compared to the rectangular.

6. More hangers/supports will be needed

About 50% more. Most rectangular ducts need to be supported at least every 8’ – 0”. For round and flat oval spiral ducts, that support spacing is 12’ – 0”.

7. More insulation will be added

It’s going to take more square feet of insulation to cover the increased perimeter/surface area of rectangular duct.

8. Duct will leak twice as much

Rectangular duct constructed to Seal Class A (transverse and longitudinal seams sealed, openings for rotating shafts sealed) are expected to leak 6 cfm/100 ft2 duct surface area at 1” WG. Round and flat oval spiral ducts constructed to Seal Class A are expected to leak 3 cfm/100 ft2 duct surface area at 1” WG.

9. ASHRAE Standard 90.1-2013 Energy Code might not be met

It states “Ductwork and all plenums with pressure class ratings shall be constructed to Seal Class A, as required to meet the requirements of Section 6.4.4.2.2…” (the Duct Leakage Class).” It doesn’t say you have to test it, but you are expected to meet the same standards as the duct you are required to test. That Duct Leakage Class is 4 cfm/100 ft2 at 1” WC. Rectangular duct meeting the required Seal Class A is expected to leak 50% more than the allowance. Round and flat oval spiral duct is expected to leak only 75% of the allowance. Perhaps we should pause a moment to let these numbers sink in. If more than 33% of your total square footage of ductwork – high pressure, low pressure, medium pressure, return air, and exhaust – is rectangular duct, even constructed to Seal Class A, instead of round and flat oval spiral duct, the duct is designed to fail!

10. More duct sealant will be needed

Even if you don’t test the duct to find that you’ve failed the energy code, you’re still required to construct the duct to Seal Class A. When you do that, you’ll get a pretty good picture of why rectangular duct leaks at least twice as much as spiral duct. First of all, you have to seal the longitudinal seams of the rectangular duct. You don’t have to seal the spiral lockseams of the spiral ducts. That is specifically stated in the ASHRAE standard, and testing has confirmed that spiral seam leakage is negligible – between a Duct Leakage Class of 0.02 and 0.3. Most leakage for all ducts occurs at the joints, and you are going to have about twice as many duct joints to make with rectangular duct (standard 56” lengths from a TDC coil line) versus spiral duct (commonly supplied in 10’ – 0” lengths). That by itself should give you an expectation of twice the leakage. Within the rectangular joint, the biggest culprits are those pesky corners – the same ones that cause the turbulence that gives rectangular duct its higher pressure drops and increased noise. Let’s pick an example from our chart above – 18”φ versus it’s equivalent rectangular size of 24 x 12.

Example #1

100 lineal feet of 18”φ spiral duct

Ten 10’-0” lengths of spiral duct = 9 joints

18” x π x 9 joints = 509 lineal inches of sealing

Example #2

100 lineal feet of 24 x 12 rectangular duct

100 ft x 12 in/ft x 2 longitudinal seams = 2,400 lin.in. of longitudinal joint sealing

100 feet / 56 in/section = 21.43 sections = 21 joints

21 joints x 72 perimeter inches = 1,512 lin.in. of joint sealing

Total = 3,912 lineal inches of longitudinal and joint sealing

11. It will be harder to fit the duct into the allotted space

There seems to be this mistaken idea that if ceiling space is tight or congested, your solution is to use rectangular duct. First of all, flat oval duct is going to work anywhere rectangular would, but without the pressure drops, noise, leakage, and weight. Second, anyone that’s ever seen a contractor snake a 25’ – 0” length of flex duct through an attic – and we really recommend that you don’t allow that – should understand the concept that a round duct can be maneuvered more readily than rectangular duct without compressing the area. With slip-joint construction you trim duct lengths of round and flat oval spiral ducts without compromising their integrity or performance. Have you ever looked at rectangular duct that’s been “field adjusted”? It’s usually not appealing. In any case, you shouldn’t base the design of a commercial duct system on the premise that what you draw probably won’t fit, so you need to plan for the contractor to have to change everything in the field.

12. The duct won’t be easier or faster to get

This one really doesn’t make sense for commercial construction, yet we hear it all the time. Yes, many sheet metal contractors have their own shops and could – in theory – go out there and make the duct for your project right now. In the real world, they try to keep their shops busy and your job will wait in line. If their shop is busy, their cost to make rectangular duct will be much higher. If you really need the duct fast, there are dozens of places within a one-day shipping frame of your jobsite where you can find round spiral duct and fittings in stock for immediate shipment in the size range you should need on a fast-track project. Most commercial duct projects go through months of coordination and detailing, so getting any duct – regardless of what you think shop lead time is – is a matter of planning, not “availability”. Round and flat oval spiral duct are neither hard to find or non- competitive.

Do you see where we’re going with all this? The numbers stack up overwhelmingly in favor of round and flat oval spiral ducts. The ASHRAE Handbooks and Design Guides tell you to use round and flat oval ducts over rectangular ducts. ASHRAE research projects prove better performance from round and flat oval ducts. Other testing projects – from manufacturers, trade groups and government organizations like the Department of Energy – support the advantages of round and flat oval duct over rectangular. Countless real-world examples where a contractor or manufacturer converted a mostly rectangular duct design to round and flat oval spiral duct, have proven you can get better performance at a better installed cost.

If you don’t use those symbols above and indicate you want round and flat oval duct for your project, you will almost certainly get rectangular duct. It will not perform as well, it will probably cost more, and you will have done the owner no favors. As obvious as it may be that you should have used round and flat oval duct, the contractor probably needs the rectangular work to pay for his shop and no one has the time to re-design the job and show how the duct system could have been much better.

If you just haven’t been designing round and flat oval spiral duct because you couldn’t find the right symbols, give us a call. We’ll help you add them to your library.

Browse OurDuct Solutions

Spiral Pipe of Texas (SPOT) fabricates high quality, MADE IN THE USA sheet metal products for the heating, air conditioning and ventilation (HVAC) industries.